1. Our Vision

OUR VIEW OF

THE FUTURE

To be the GCC’s leading oileld equipment manufacturer and

service provider of choice in the industry.

2. Our Mission

WHY WE EXIST

To provide quality service to our customers; create value for

our employees and in communities where we operate in; and to

maintain world-class industry standards that generate the best

return for shareholders’ investments to a level that meets and

surpasses their expectations.

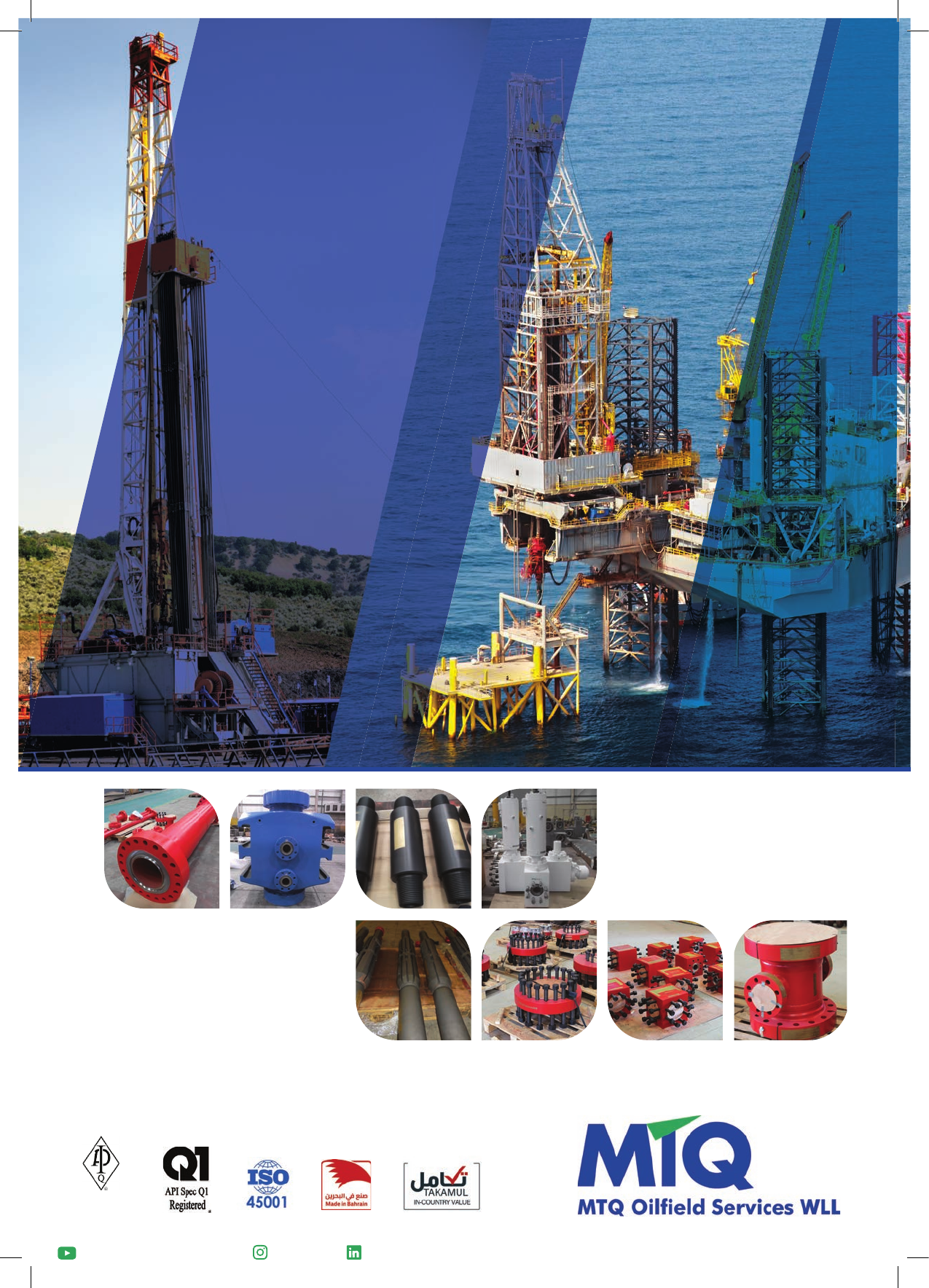

3. Corporate Prole

WHO WE ARE

Established in 1969, MTQ Group has become a trusted and

leading engineering solution provider for oileld equipment

companies around the world.

In 2009, the company was incorporated in the Kingdom of

Bahrain as MTQ Oileld Services W.L.L (MTQOS) and became

a wholly-owned subsidiary of MTQ Group, which is listed on

the Singapore Exchange – earning a reputation as a trusted

services provider for the oil and gas industry in the GCC.

With more than 30 years of experience in the oileld engineering

services, MTQ oers its clientele a range of services that include

fabrication of steel structures and advanced coating solutions.

The Company adheres to the highest performance standards

of the American Petroleum Institute (API) and ISO 9001:2015

Quality Management System.

We are committed to conducting business in an environmentally

responsible manner, centred on safeguarding people, equipment

and the environment by practicing the highest safety standards.

MTQ | Oileld Services W.L.L.

01

WE AIM TO

MAINTAIN

WORLD-CLASS

INDUSTRY

STANDARD.

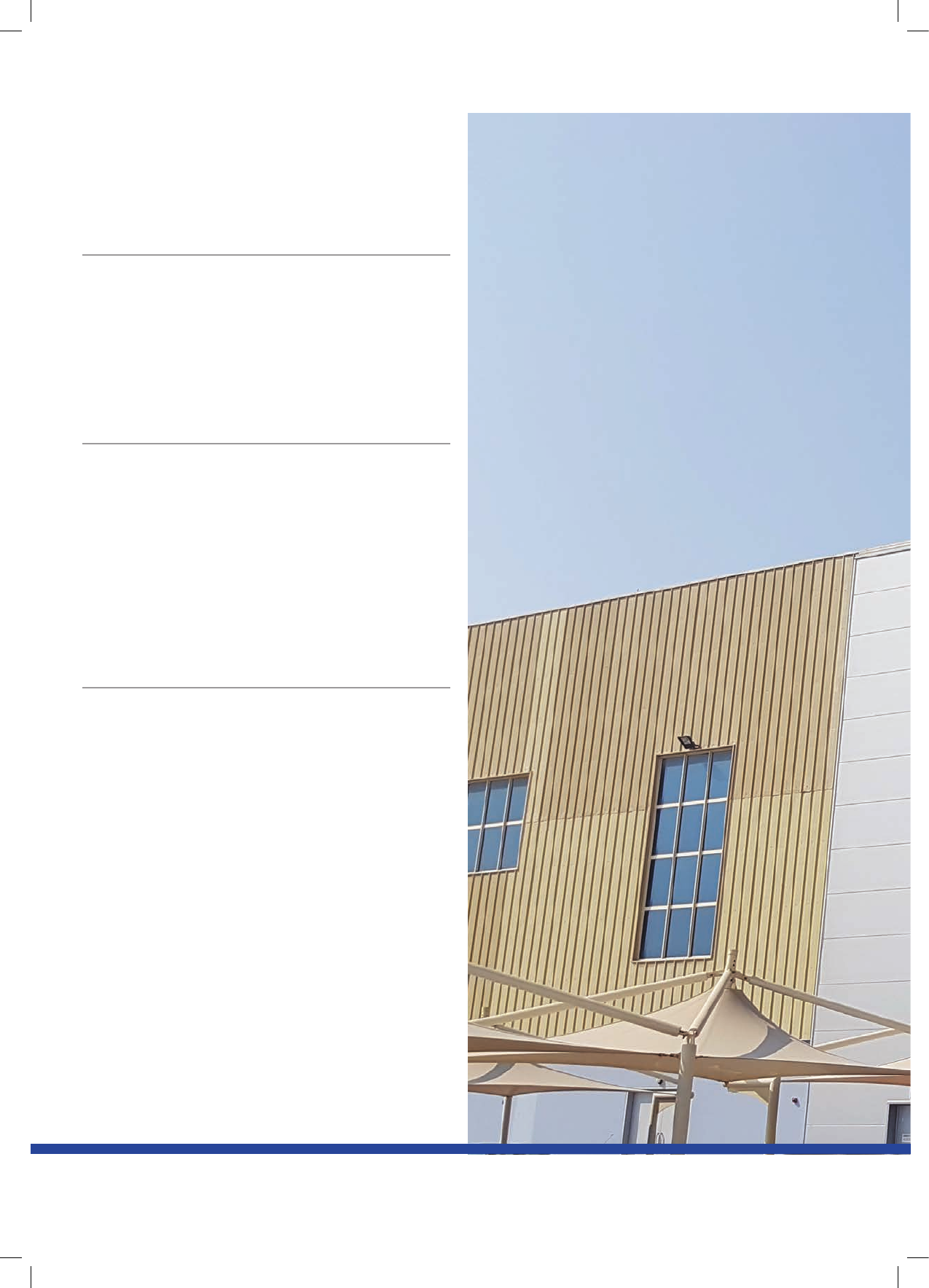

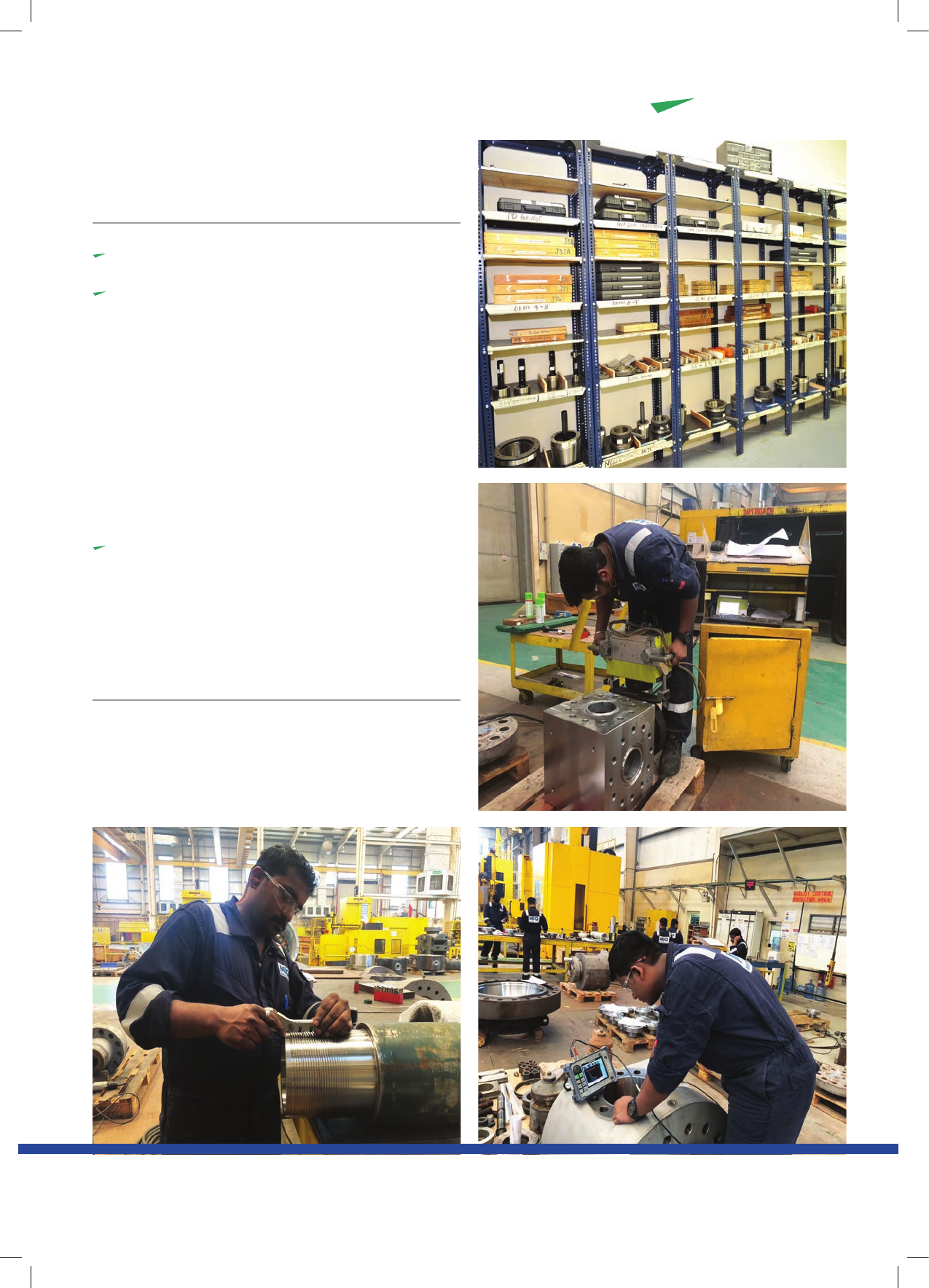

MTQOS has a world class state-of-the art advanced facility

approved by global OEMs for validation of various components

to ensure higher and consistent level of quality. We manufacture

equipment as per API 6A, 16A, 16C, 5CT and 7-1 as well as

special fabrication of BOP test plugs, Wear Bushing, Running

Retrieving Tools tec. for OEMs. MTQOS does refurbishing/

repair of wellhead equipment (Xmas Trees, Tubing/Casing

Spools, Valves and BOPs) for various world known OEMs.

4. FACILITY

ONE OF THE

LARGEST

OF ITS KIND

IN THE INDUSTRY IN

THE MIDDLE EAST

(8,000 m

2

built up area)

02

MTQ | Oileld Services W.L.L.

03

API Q1-1345: Manufacture of Drill-Through

Equipment, Drill Stem Elements and Well-

head Equipment for the Oil and Gas Industry.

API 6A-1293: Wellhead and Christmas Tree

Equipment.

API 16A-0302: Drill Through Equipment.

API 16C-0409: Choke and Kill Manifold.

API 7-1-0949: Rotary Drill Stem Elements.

API 5CT-1894: Casing and Tubing.

Grant Prideco Premium XT & HT & VX

connections.

ISO 9001:2015.

Voestalpine Premium Connection, VAGT, VA

Superior, VA Roughneck & VA Xplorer.

Tenaris & Hydril Premium connections

ISO 45001.

5. API & OTHER

CERTIFICATES

Manufacture and Recertication:

Flanges, Weld Neck Flanges, Blind Flanges, Slip On Flanges, etc.

Double Studded Adapter (DSA) and Studded Blocks.

Mud Cross, Adapter Spool and Drilling Risers.

Choke and Kill Manifolds.

Refurbish and repair:

X-MAS tree

BOP.

Manufacture and repair:

Crossover Subs.

Bit Subs.

Manufacture:

Couplings (BTC, EUE, etc.).

Drifts (Teflon, Steel, Aluminum).

Valves.

BOP Test Plug.

Wear Bushing.

Wel Intervention and Wireline Tools.

Threading and re-threading connections:

Drill Pipe, HWDP, Drill Collar, TBG, CSG.

Voestalpine: VAGT, VA Superior, VA Roughneck, VA Explorer.

Grant Prideco XT & HT.

API 7-1 Connections (REG, IF, XH, etc.).

API 5CT Connections (EUE, NUE, STC, BTC, etc.).

Services:

Machining.

Coating & Painting.

Welding & Heat Treatment.

NDT (UT,MPI, PT).

Hardness Inspection.

Pressure Testing (up to 30,000 psi).

Supply:

Ring Gaskets.

Stud Bolts.

Clover Tool Co. Hydrostatic Test Units.

Drilling Handling Tools.

Rotary Tables & Rig Floor Matting.

Shaker Screens.

ASME Flanges.

Torqueing Equipment.

6. PRODUCTS

& SERVICES

Saver Subs and Float Subs.

Lifting Subs and Lifting Plugs.

Mud Pump Modules.

04

MTQ | Oileld Services W.L.L.

05

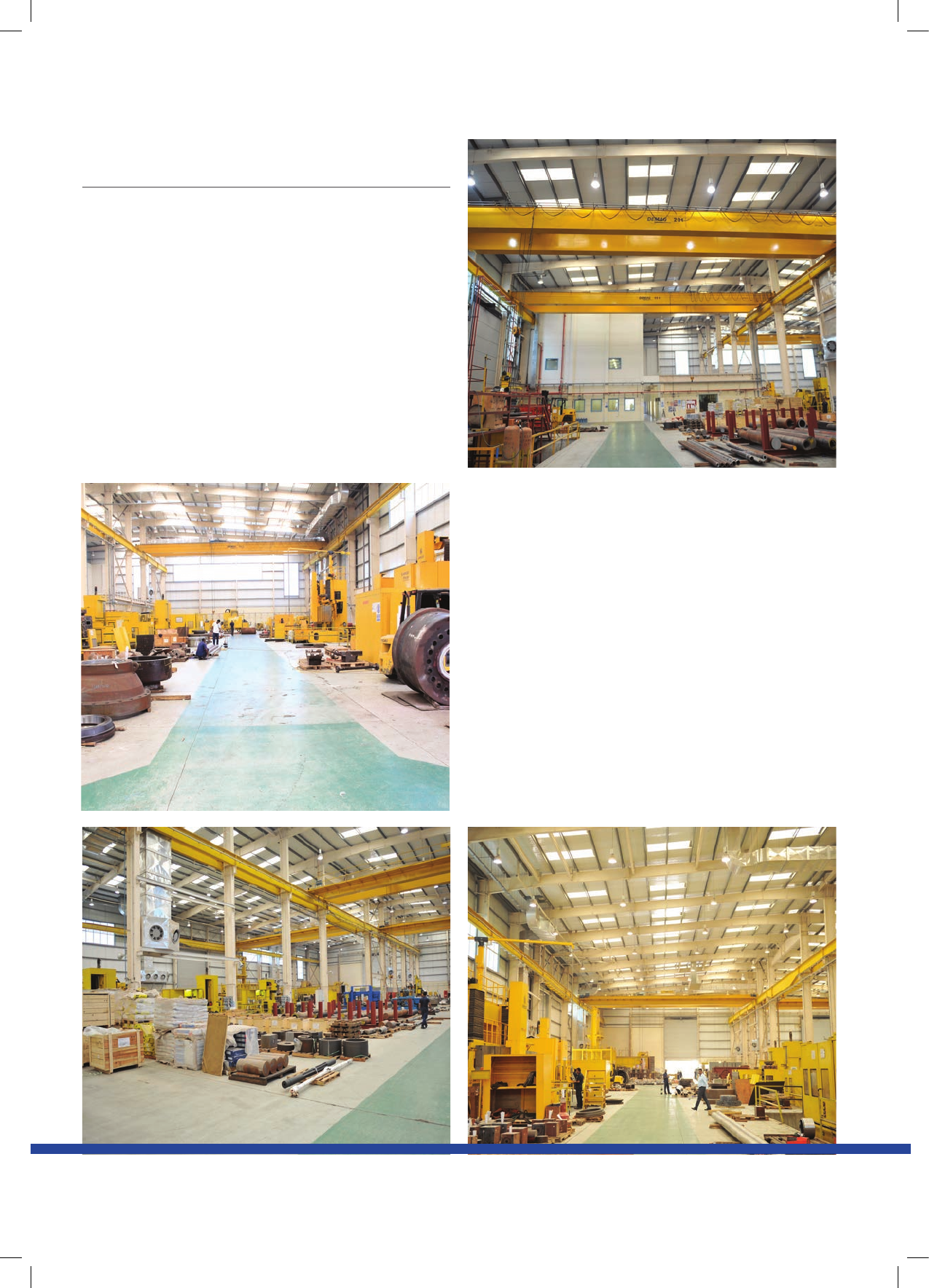

MTQOS has invested heavily in machine and tooling to support

rising demand from Oil and Gas and Petrochemical sector.

MTQOS has:

CNC Vertical Turning Lathes.

CNC Horizontal Milling/Boring Machines.

CNC Vertical Milling Machines.

CNC Horizontal Turning Lathes.

Manual Horizontal turning Lathes.

Dual Spindle Machining Center

Mill turn technology

7. MACHINE SHOP

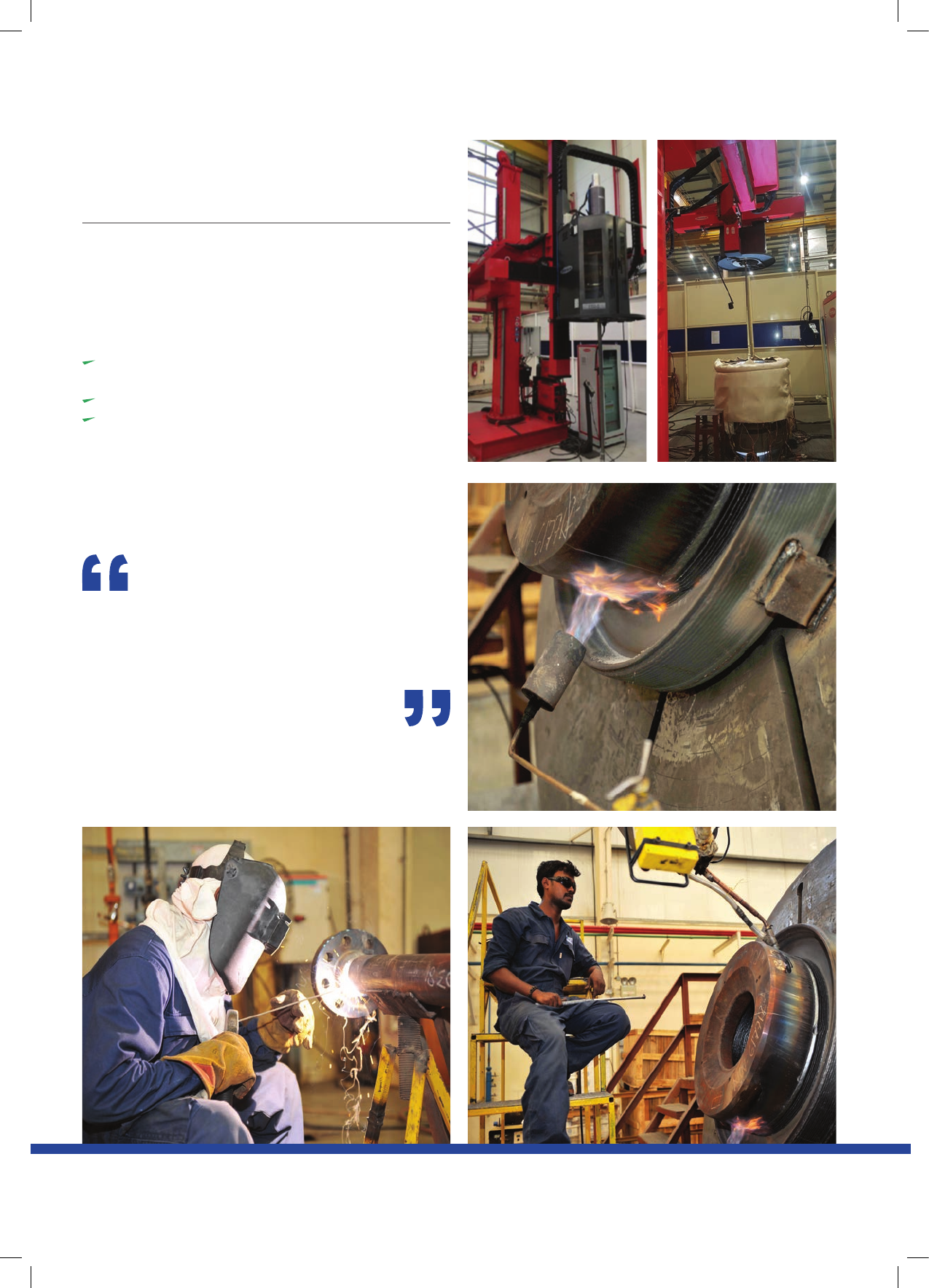

8. WELDING

DEPARTMENT

Access to over 100 qualied weld

procedures for all types of materials and

pre/post weld heating furnaces.

THE NEW AGE IN

WELDING SUPREME

MTQOS has:

Fronius Fully Automatic Cladding Machine with capability of

welding through bore IDs with Inconel 625 overlay.

Positioners with Semi-Automatic Sub-Arc Welding.

Assorted collection of manual Sub-Arc & TIG welding

machines.

06

MTQ | Oileld Services W.L.L.

07

10. HEALTH SAFETY

& ENVIRONMENT

MTQ is committed to providing and maintaining a safe and

healthy work environment for all our employees and has con-

tinually strive to improve our health, safety and environmental

performance. We are certied under the Occupational Health

and Safety Management System 18001-2007.

9. QUALITY CONTROL

DEPARTMENT

Inspection Services as per API standards using latest

technology and equipment.

Our team of QA/QC uses a list of methods for dimensional

and physical inspection throughout the process of

manufacturing. This includes:

MTQ can provide QC inspectors/technicians to perform eld

inspection services and surveys for onshore and oshore.

. 1 Visible and Fluorescent Magnetic Particle Inspection

including Coil and Yoke.

. 2 Liquid Penetration (LPI) including Fluorescent UT/RT.

. 3 Coordinate Measuring Machine (CMM).

. 4 Thread inspection by gauges and prole projector.

. 5 Hardness Inspection (Brinell and Rockwell).

. 6 Positive Material Identication.

. 7 Our Quality department has a majority of tools and

gauges in house for almost all thread types.

12. COATING

SERVICES

MTQ can also provide services for Phosphating (Zinc and Manganese),

Xylan (all types) and Everslik (all types).

11. TESTING

& ASSEMBLY

Pressure testing up to 30,000 PSI Hydro-test and 15,000 PSI Gas Testing.

This enables MTQ to provide complete end-to-end solutions to its

customers from product conceptualization through to designing,

manufacturing, validation and testing.

08

13. OUR

CLIENTS

We serve a wide range of customers in the Oil & Gas industry such as OEMs,

Drilling Contractors, and Service Companies.

09

MTQ | Oileld Services W.L.L.

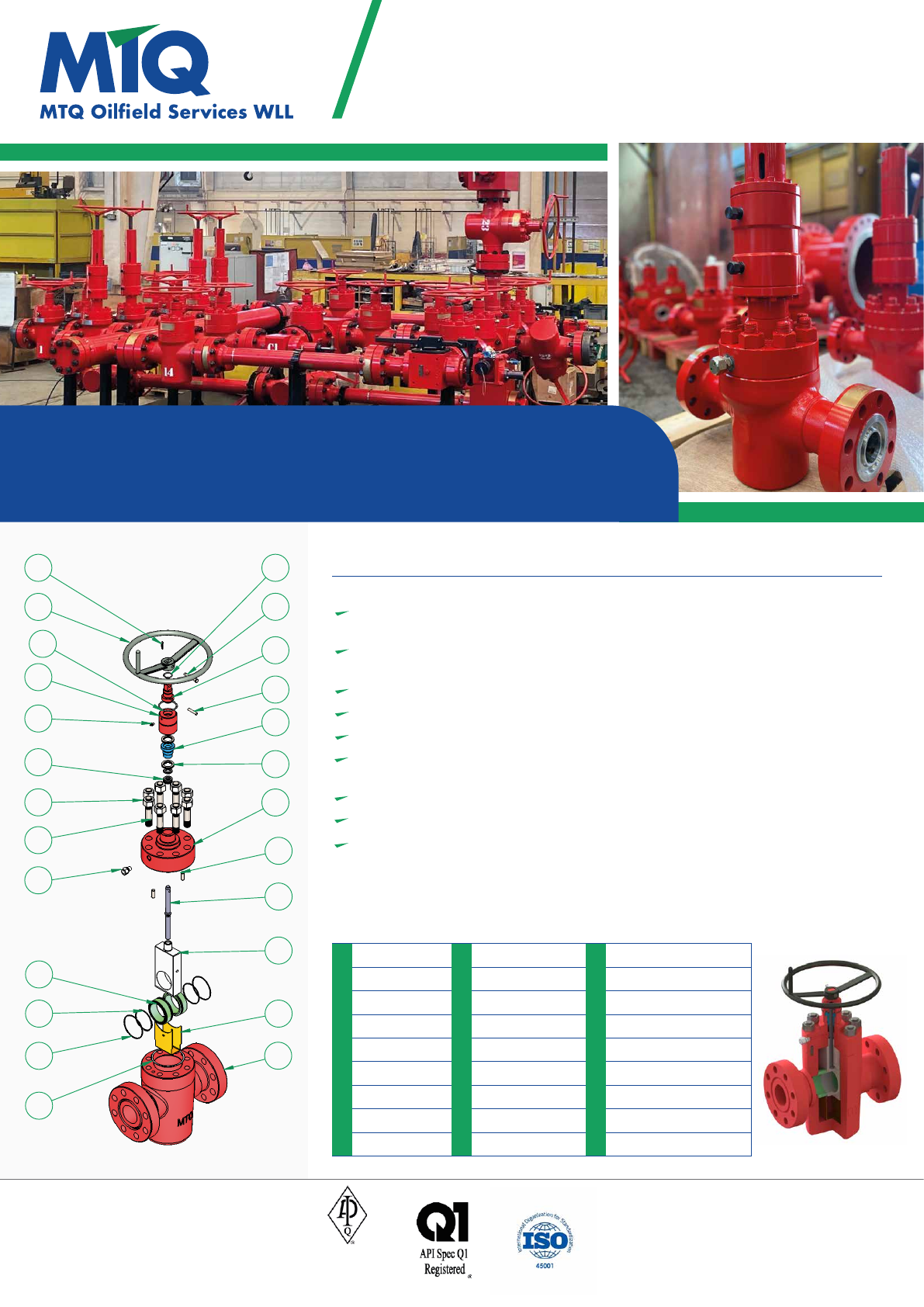

MTQ Oileld services is a licensed manufacturer of API 6A gate valves. Our manual and

hydraulic gate valves can be used for ow lines, BOP stacks, drilling manifolds. MTQ

valves are manufactured as per API 6A latest edition and in compliance with Aramco’s

Well Control Manual. Our range of valves incorporate forged bodies and single piece

seats without body bushings. Valves are available in all bore size.

Packing retainer allows for replacement of thrust-bearings whilst valve is under

pressure.

Injection port allows for lubrication of gate and seat assembly and offers the possibility

to relieve trapped pressure upon back seating the stem.

Wider choice of materials for the components.

Offers manual and/or hydraulic operation.

Thrust bearings reduce operating torques.

Shear pin prevents excessive loads being applied via hand-wheel and protects

internal parts from damage.

Back Seating of stem offers the possibility of replacing stem packing.

Gate and Seats can be easily assembled without the requirement of special tools.

Gate is designed to prevent line sediments from entering the body cavity and prevents

pressure locking when the upstream pressure is reduced.

Manual Gate Valves

Body

Gate Guide

Seat

Seal Ring Inner

Seal Ring Outer

Gate

Alignment Pin

Stem

Bonnet

Bonnet Gasket

Double End Stud

Nut

Stem Packing Set

Packing Gland

Thrust Bearing

Stem Adapter

Stem Shear Pin

Bonnet Cap

Hand Wheel

Hand Wheel Pin

Spilt Pin

O-Ring

O-Ring

Grease Fitting

Grease Fitting

Name Plate (Not Shown)

Rivet (Not Shown)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21 22

23

24

25

Features & Benets

Gate Valves

19

20

21

22

23

24

25

26

27

10

11

12

13

14

15

16

17

18

1

2

3

4

5

6

7

8

9

API Q1-1345

API 6A-1293

API 16A-0302

API 16C-0409

API 7-1-0949

API 5CT-1894

Q1-1345

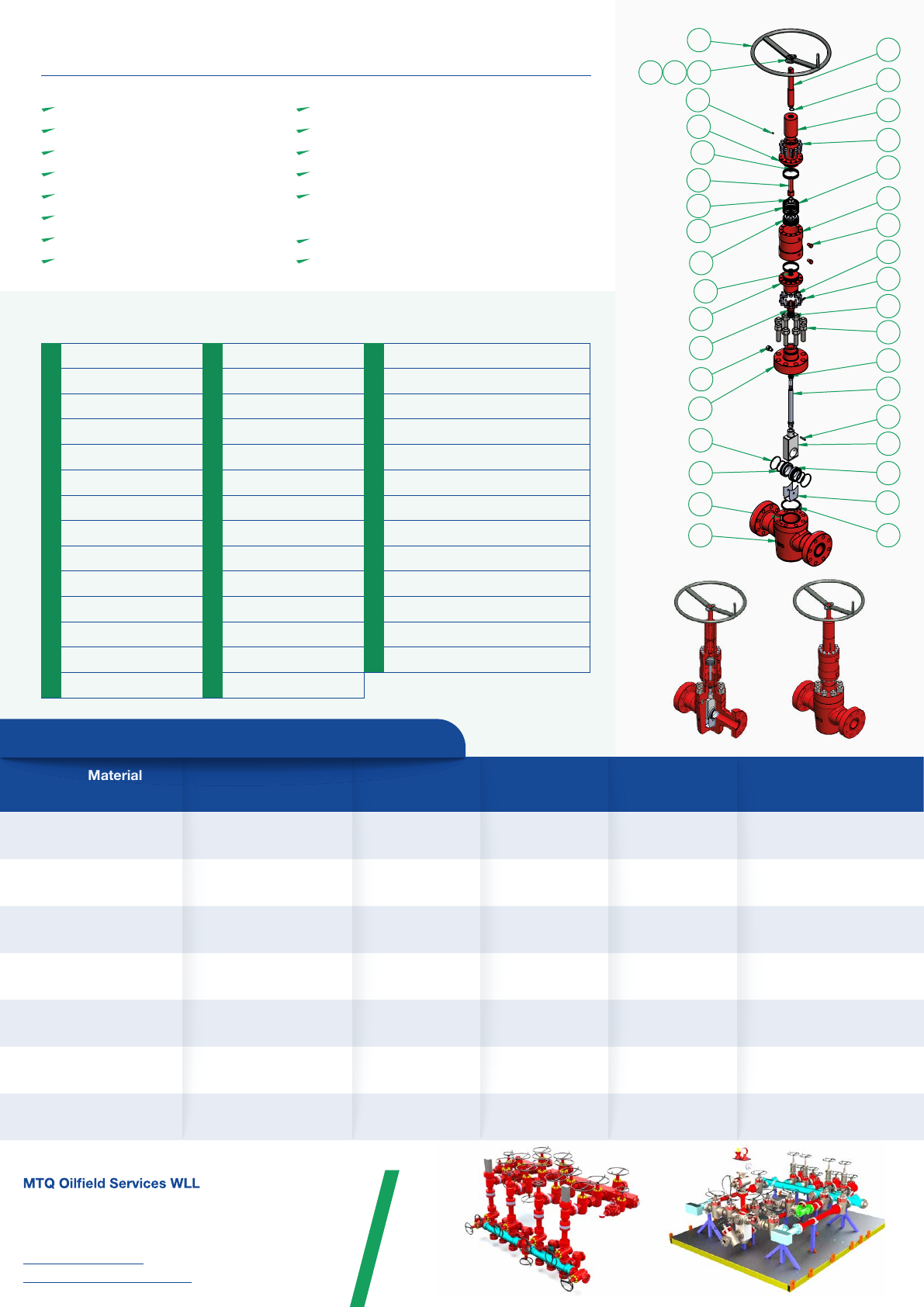

Forged body and bonnet.

Bi-directional sealing.

Metal to Metal seat.

Solid single piece slab gate.

Single piece seats.

No body bushing.

Full bore.

Manual and hydraulic options.

Design & Specications

API Material classes AA to HH.

Performance Requirement PR1 & PR2.

Product Specication Levels PSL 1 to PSL 3

Non elastomeric sealings.

PTFE spring energized lip seals for stem

packing.

Metal to Metal back seat.

API 6A Flange End-to-End dimensions.

Standard Valve Trim Materials

Transparent Cover (Not Shown)

O Ring

Hexagonal Socket Head Cap

Screw

Hexagonal Nut

O Ring

O Ring

Bonnet

Stem Pin

Grease Injection Fitting

Injection Nameplate (Not Shown)

Rivet (Not Shown)

Stud And Nut Set

Body

Retainer Plate

Seat

Seat Ring (Inner)

Seat Ring (Outer)

Gate

Gasket

Stem

Stem Packing

Set Screw

Packing Gland

O Ring

Cylinder Head Lower

Pipe Plug

Cylinder

O Ring

Back Up Ring

Piston

Cylinder Head Upper

Indicator Stem

Transfer Lever

Transfer Lever Nut

O Ring

Handwheel

Hexagonal Bolt

Hex Nut

Indicator Nameplate

Grease Fitting

Hydraulic Gate Valves

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

1

34

5

6

7

8

9

10

11

13

15

16

14

18

19

20

21

22

23

24

25

30

31

32

34

35

36

37

39

41

33

2

12

17

26

27

28

API 6A Material

Classification

Body & Seat

Coating

Bodycote

®

/ Praxair

®

/ TC

Bodycote

®

/ Praxair

®

/ TC

Bodycote

®

/ Praxair

®

/ TC

Bodycote

®

/ Praxair

®

/ TC

Bodycote

®

/ Praxair

®

/ TC

Bodycote

®

/ Praxair

®

/ TC

Bodycote

®

/ Praxair

®

/ TC

AA - General Service

BB - General Service

CC - General Service

DD - Sour Service

EE - Sour Service

FF - Sour Service

HH - Sour Service

Building 498, Road 1508, Hidd 115, P.O. Box 60095

Manama, Kingdom of Bahrain

Tel (+973) 17166800 | Fax (+973) 1716680

sales@mtqos.com

Mtq.com.sg/Bahrain.html

Seat Material

Carbon or low alloy

steel or 410SS

AISI 410SS

AISI 410SS

Carbon or low alloy

steel

AISI 410SS

AISI 410SS

Inconel 718

Gate Material

Carbon or low alloy

steel or 410SS

AISI 410SS

AISI 410SS

Carbon or low alloy

steel

AISI 410SS

AISI 410SS

Inconel 718

Stem Material

(Coated)

Carbon or low alloy

steel or 410SS

17-4 PH

17-4 PH

Carbon or low alloy

steel or CRA

17-4 PH or CRA

17-4 PH or CRA

Inconel 718

Body & Bonnet

Material

Carbon or low alloy steel

or 410SS

Carbon or low alloy steel

or 410SS

AISI 410 SS

Carbon or low alloy steel

or CRA

Carbon or low alloy steel

or CRA

AISI 410 SS or CRA

Low alloy steel cladded

with inconel 625

MTQ Oileld Services WLL

Building 498, Road 1508, Hidd 115, P.O. Box 60095

Manama, Kingdom of Bahrain

Tel (+973) 17166800 | Fax (+973) 1716680

sales@mtqos.com

Mtq.com.sg/Bahrain.html

Towards Khalifa Bin Salman Port. Bahrain International Investment Park, Sheikh Salman Industrial Estate.

Building 498, Road 1508, HIDD 115 P.O. Box 60095, Manama Kingdom of Bahrain,

[26.222817, 50.669200]

https://goo.gl/maps/gtoE22T2tbD2

MTQ Location in Bahrain

Authorized agents for:

MTQ Oilfield Services

MTQ Oilfield Services W.L.L

mtq_os